- May 26, 2025

- By: admin

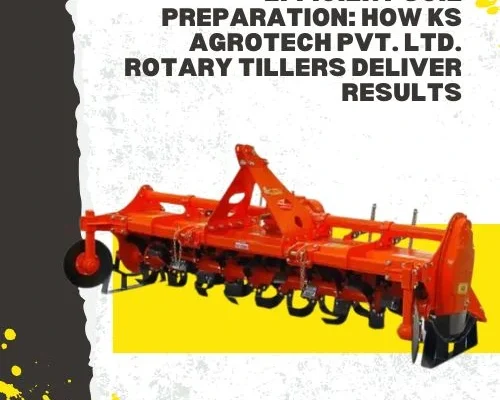

- in: Rotary Tiller

One of the farm implements that is the most important in modern farming is a rotary tiller. It assists farmers in preparing land fast, enhancing soil structure, and saving time and labor. But, just as with any farming equipment, the efficiency and duration of life are very dependent on maintenance. Failure to maintain a routine will result in a high frequency of breakdowns,a decrease in efficiency, and increased cost of repair. This manual contains useful and efficient tips to maintain the rotary tiller in practice, which could help ensure maximum longevity and reliable working in the field.

The most common thing to do before beginning any maintenance procedure is to have knowledge of how the rotary tiller works and what the major parts play. The components of the machine include blades, gearbox, PTO shaft, bearings, seals and frame which all combine to produce the machine that is to operate under heavy load and soil pressure. Since Rotary Tiller uses involve continuous contact with soil, stones, moisture, and crop residue, wear and tear is unavoidable. Early signs of damage are revealed through proper inspection and major failures are prevented.

One of the easiest but most neglected maintenance procedures is the cleaning of the rotary tiller after usage. Blades, frame and bearings may become rusted and corroded with soil, mud, crop residue and moisture clinging to them.

Having completed the field work, clean blades and housing with water or compressed air. Make sure that the machine is thoroughly dry before storing. Maintenance of the tiller will enhance visibility during inspection and eliminate long term damages occasioned by moisture retention.

The most important working components of a rotary tiller are the blades. Blades that are dull, bent, or cracked increase the quality of tillage as well as impose undue stress on the tractor and gearbox.

Always check the condition of the blade and change the worn out or damaged ones promptly. Tighten loose bolts and get blades in place. Both sharp and balanced blades enhance soil pulverization besides fuel consumption and mechanical stress thereby increasing the life of the machine as a whole.

Lubrication is a major factor in the prevention of friction damage. The bearings, chains, PTO joints and moving parts should be greased according to the schedule given by the manufacturer.

Always apply prescribed lubricants and inspect grease points prior to each large operation. Lack of lubrication may lead to overheating, bearing failures and damage in the gearboxes. Frequent greasing will guarantee that it operates smoothly and that the parts will not wear out too soon.

The gear box is used to transmit heavy torque and should be taken care of. Verify the level of oil in the check at regular intervals and refill where necessary. Worn out or dirty oil must be changed after every suggested time.

The disregard of gearbox maintenance may lead to a faulty sound during operation, loss of power, and expensive repairs. Clean oil maintains good lubrication of inner gears and augments the longevity of gears.

The rotary tiller receives power through the PTO shaft which connects the tractor to the rotary tiller. Check it on alignment, wear and correct locking. Lubricate universal joints and telescopic parts on a regular basis.

Make sure there are safety shields, working. A well-maintained PTO shaft ensures efficient power transfer and protects both the operator and machine during operation with a Rotary Tiller for a tractor.

Good storage contributes greatly to the life of a machine. It is important to keep the rotary tiller in a dry covered place which is free of sunlight and rainfall. Lift the machine slightly above ground in order to avoid dampness.

Prior to long-term storage, be sure to clean the machine and lubricate moving parts, and use anti- rust oil on the open metal parts. A good storage behavior would help avoid corrosion and minimize the problem of starting up next season.

Consistently inspecting them prevents minor problems and ensures that minor ones are not developed into big problems. Check nuts, bolts, seals and bearings and frame alignment often. Pay attention to unusual sounds during the operating process that usually signify internal problems.

Timely repair not only saves money but also protects the entire Rotary Tiller machine from cascading failures. Preventive maintenance is never expensive as compared to emergency repairs.

That, always consult the manufacturer manual and refer to it when it comes to the maintenance intervals, lubrication point and safety instructions. Depending on the design and use conditions, each model might have certain requirements.

The major manufacturers of agricultural equipment such as KS Agrotech PVT LTD give precise instructions to ensure their equipment is well maintained to ensure that they are safe to the farmers.

Good maintenance has a direct effect on the operating costs. Well maintained machines consume less fuel, work better in the field, and breakdown less often. Over time, this helps farmers get better value against the Rotary Tiller price they invested in, making maintenance a smart long-term decision rather than an expense.

Rotary tiller is a long-term investment that is very important in land preparation and soil health. By cleaning, checking the blade, maintaining the required level of lubrication, taking care of the gears, and making sure that the machine is well stored, farmers can considerably prolong the life of their machine. Regular maintenance does not only enhance performance, but also provides safe and reliable operation with every season. With these tips in mind, farmers will be able to gain as much as possible without jeopardizing their investment in equipment in the future.