- May 26, 2025

- By: admin

- in: Rotary Tiller

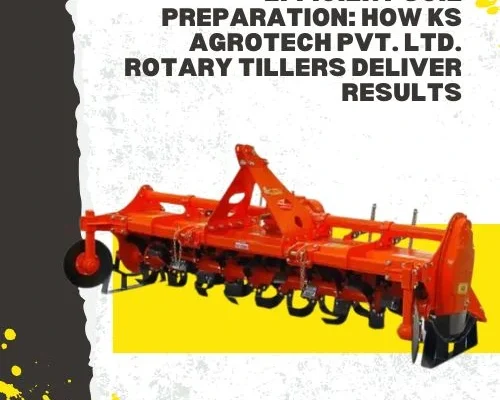

It is at KS Agrotech Pvt. Ltd. that we understand the importance of better quality farm equipment being in use to boost efficiency and productivity to their maximum potential. Rotary tillers, being the most critical equipment, are important land preparation machinery. Ranging from a tractor-mounted rotary tiller to an independent tiller machine, it is absolutely necessary that the right one be selected to obtain the maximum farm yield.

This is an authoritative guide to the uses of rotary tillers in agriculture, crucial things to know when buying, prices of rototillers, and some of the most frequently asked questions by farmers. After reading this guide, you shall be sufficiently equipped to make your own informed choice.

It is a farm tractor machine that aerates and breaks up the ground with rotating tines. It is employed to sow in soil by pulling out weeds, breaking the soil, and incorporating green manure or organic manure. A rototiller with a three-point hitch is attached to the back of a tractor and powered by a tractor’s power take-off (PTO). It is a self-propelled machine that is independent and best suited for application in small farmyards or backyards.

Rotary tiller for tractors has numerous applications in agriculture and gardening. Some of the most common applications of a rototiller in farming are:

The diagram of a rotary tiller gives one a clear cut-out of important features such as the PTO shaft, gearbox, and tines. With such knowledge, farmers can be in a position to maintain and operate the machine effectively, resulting in maximum performance and lifespan.

The best rototiller to utilize with a tractor relies on its horsepower (HP).

A wider tiller is effective but needs more power.

The effectiveness of a tiller depends solely on the blades.

An adjustable depth rotary tiller machine allows room for adjustment to fit different crops and grounds.

Knowing the drive system of the tiller assists in deciding on durability and performance.

Buying a heavy-duty tiller machine means long-term performance.

Pricing- what to anticipate:

The rate of a rototiller depends on factors like cloth energy, capabilities, and supposed use. here’s a standard breakdown of price tiers:

Seasoned Tip:

Rather than focusing entirely on the rotary tiller price, bear in mind performance, durability, and long-term advantages. Making an investment in a model from a reliable brand like KS Agrotech Pvt. Ltd. ensures better soil conditioning and elevated farm productivity.

A rotary tiller diagram will typically highlight important components, giving farmers notice about maintenance and usage.

Periodic maintenance to such components ensures long life and optimum performance.

The most suitable rotavator for tractors varies with the tractor’s HP and farm size. For small farms, a 4-5 ft tiller is ideal, while commercial agriculture requires 6-7 ft types.

The cost of a rotavator depends on usage and lifespan. The lowest quality ones cost around ₹80,000, whereas the high-cost, heavy-duty ones cost between ₹5,00,000 or more according to specifications and brand value.

Replace blades after 100-200 hours of use. Sharpening of blades every time will help increase the blade’s life.

Yes, but the rocky ground needs heavy-duty rotary tiller machines with heavy-duty tines not break.

A rotavator is also used in tilling the soil deeper, whereas a cultivator will be used for aeration and weeding in the shallow top part of the soil.

We ensure to offer only high-quality agriculture equipment that contributes to productivity in KS Agrotech Pvt. Ltd. If the right rototiller is selected for use on a tractor, soil preparation can become effortless, and subsequent yields will increase.

Need a dependable rotary tiller? Visit KS Agrotech Pvt. Ltd. and discover high-performing models today! ?