- February 12, 2026

- By: admin

- in: Updates

The harvesting of rice is a very crucial process in the agricultural cycle which directly influences the quality of yield, the percentage of grain recovered and the entire profitability. Strong harvesting methods also guarantee that there are minimal losses of crops that are transferred to the storage facility. As labor costs increase and harvesting periods grow shorter, it has become necessary to enhance efficiency among large and small-scale rice farmers.

Time is an essential factor in harvesting of rice. Late harvesting may result in shattering of grains, moisture disorders, infestation by pests and lodging. Conversely, premature harvesting can lead to undeveloped grains and reduced milling. Planning helps to ensure the crop is harvested at the best possible maturity and maintain the grain weight and quality and to minimize the losses that may occur after harvesting.

Conventional harvesting procedures of rice depend mostly on the manual labor. These methods are time consuming and labor intensive although they are effective on very small plots. Variations in cutting height, inconsistent bundling and failure to transport to storage facilities promptly breed losses. The weather dependence also adds to the process, particularly during the high seasons like the harvest times where the supply of labor is minimal.

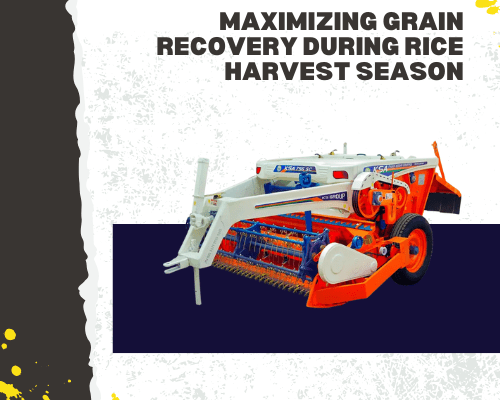

Rice harvest has already been changed through mechanization, which has minimized the need to use labor and increased the pace of work. The modern harvesting machines enable the farmers to harvest more lands in a short period of time without having different cutting and consequently handling the crops effectively. The use of machines such as a paddy reaper helps streamline the cutting process, enabling faster collection and reducing grain losses caused by over-handling.

Harvest productivity does not cease in the field. After cutting it is also important to handle properly. The transportation of rice sheaves should be timely to avoid the absorption of moisture and its growth by fungi. Well-calculated use of logistics like tractor trolleys or conveyors are beneficial in minimizing spillage and ensures that the grain is clean. Delicate piling and shielding against rain make sure that the crop harvested is not spoilt before threshing.

Threshing is a very important connection between harvesting and storage. The effective threshing process separates grains and straw without destroying kernels. Threshers in the form of machines provide consistency in production and less damage than hand beating. Post-threshing cleaning eliminates chaff, stones and impurities which enhances storage and market value.

The work put into harvesting is not lost by means of efficient storage. The rice must be dried to allow safe moisture levels then stored to avoid molds and insect infestation. Storage facilities must be well ventilated, moisture resistant and with pest control measures. To ensure that the grain stored is of high quality, farmers ought to observe temperature and humidity variations in the grain on a regular basis.

Enhanced efficiency of harvesting has a direct effect on the profitability of the farm. The low cost of labor, reduced loss of grain as well as enhanced products will result in increased returns in the market. The effective harvesting and storage practices also enable farmers to have more time to get the fields ready to the next cropping cycle leading to an increase in the productivity of the farms.

Since it is a step of rice harvesting, every moment of the field cutting to safe storage is the key factor in defining the final yield and income. The use of effective harvesting methods, handling and effective storage practices can assist farmers to minimize losses and maximize returns. It is possible to guarantee the effective flow of field-to-storage operations and preserve the quality of grain and long-term sustainability by concentrating on the timely operations and modern solutions offered to rice farmers.